With a network of dental labs as large as AmericaSmiles, communications with hundreds of lab owners

provides us with unique insights into cost saving practices sometimes overlooked by management. Speaking

with those in the industry it has become apparent that many operators are unaware of the necessity of a

consistent proactive sintering oven cleaning regiment. Properly purging your oven not only provides a

consistent end product but helps prevent operational dysfunctions, expensive remakes, and oven repairs.

Several reasons why you should purge your dental sintering oven:

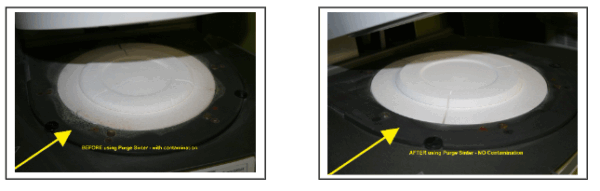

- Contamination builds up from oxides in coloring agents used to shade zirconia crowns or bridges.

During the Zirconia sintering process coloring agents release oxides resulting in contamination build up

on the oven’s interior. Both acid and water-based coloring agents produce build up that will eventually

result in a flaking contaminating zirconia and shorting the life of sintering beads. - These oxides cause discolor of Zirconia during sintering.

This discolor is usually a greenish/yellowing with the Zirconia units appearing dull with a loss of

translucency.The end-result often is decreased productivity and increased cost because of required

remakes. - The oxides also build up on the furnace coils, heating elements and internal furnace parts.

If not maintained regularly, contamination build up will continue until a splay occurs resulting in flaking

and powdering during the sintering process. The result is contaminated Zirconia and additional

remakes. This build up also affects temperature readings making quality control difficult. Another

unfortunate result may be the need replace an expensive heating element or coil.

Purge SINTER used regularly will eliminate all of the above concerns as a result of build-up

contamination.

Purge SINTER is a unique double activated ion and oxide absorbing material especially manufactured to

eliminate all contaminates that can cause discoloration in zirconia dental delimitation. Coloring liquids used in

Zircona crowns, copings and frameworks can build up inside an oven and cause color problems. With the

implementation of Purge SINTER coloring liquid contaminants are completely absorbed out of the dental

furnace. Purge SINTER will extend oven, elements and thermocouple life and maintain thermocouple accuracy.

For maximum results, AMS recommends purging your oven once a week.

DIRECTIONS:

- Fill the provided crucible with Purge SINTER

- Place the crucible containing Purge SINTER in your sintering furnace

- Low Temp: 500 C / 900 F

- High Temp: 800 C /1475F

- Heat Rate: 40 C / 100 F per minute

- Hold Time: 10 minutes

- Cool Time: 5 minutes

- DO NOT EXCEDE 800 C /1475 F

- SHAKE WELL BEFORE USE AmericaSmiles is now offering Purge SINTER with membership discounted prices.

Join us at LabDay -

Join us at LabDay -