In a busy dental lab, time is more than money—it’s your competitive edge. Delays, inefficiencies, and miscommunications add up quickly, eating into margins and affecting client satisfaction. While many labs focus on growing case volume or adding new equipment, the biggest gains often come from addressing the bottlenecks already slowing things down. By taking a closer look at how your team works day to day, you can uncover and fix common time wasters that drag down performance. Here are some of the most frequent culprits and proven ways to fix them.

Inefficient Case Intake

Poor intake processes are a leading cause of production slowdowns. Cases arrive missing key information like shade, margin lines, or delivery dates. Technicians are forced to track down details after production has already started—creating confusion, wasting time, and increasing the risk of remakes.

Solution: Standardize your intake workflow. Create a clear intake checklist that includes required fields, digital forms, or an online portal. Designate a team member to review all incoming cases for completeness before they hit the floor. Set expectations with your clients so they know what’s needed and why. Labs that improve their intake process often see immediate improvements in accuracy and turnaround time.

Poor Scheduling and Job Flow

Unbalanced workloads are a hidden efficiency killer. When departments don’t communicate effectively, one area may be buried in cases while another is idle. This leads to rushed work, overtime, and uneven turnaround.

Solution: Invest in digital scheduling tools that provide a real-time view of capacity across departments. Consider implementing a daily production meeting to review case flow and shift priorities. Assign a case coordinator or production manager to monitor the flow and adjust assignments accordingly. Efficient scheduling ensures smoother production and happier clients.

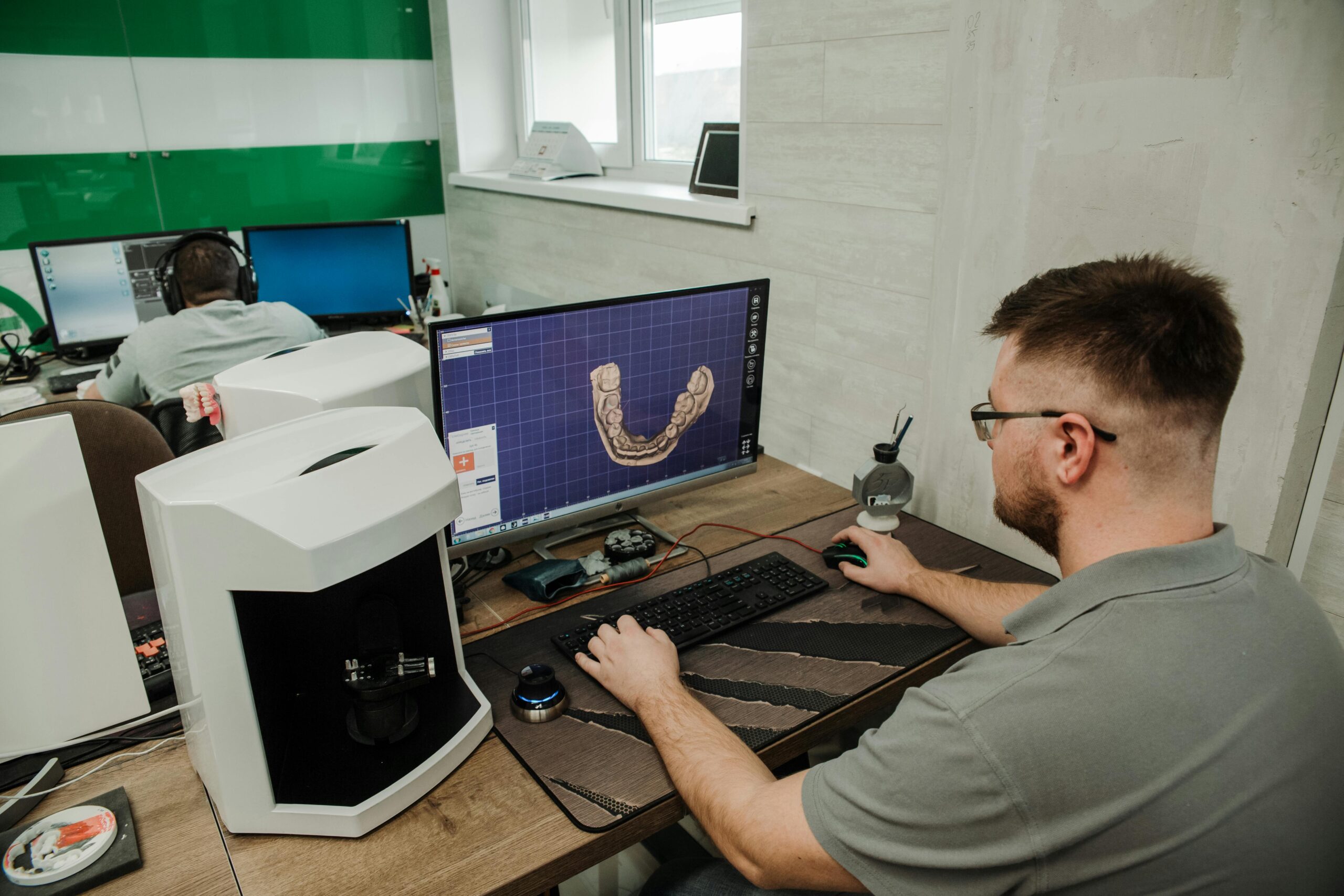

Manual or Repetitive Tasks

Highly trained technicians shouldn’t spend their time on tasks like organizing shipping labels, updating spreadsheets, or manually sorting cases. Yet in many labs, these repetitive processes remain unchanged from decades ago.

Solution: Audit your daily workflows to identify tasks that can be automated or assigned to admin staff. Consider tools that integrate with your case management software to automate labeling, billing, or file storage. Freeing technicians from these distractions allows them to focus on what they do best—delivering high-quality restorations.

Unclear Communication

Lack of communication—whether internal or with dentists—creates confusion and wasted effort. It’s common for technicians to start working on a case, only to learn later that the shade changed or the prep was incorrect.

Solution: Standardize communication protocols. Use lab management software that centralizes case notes, design approvals, and status updates. Encourage team members to document case-specific requests and train clients on how to submit revisions in a timely, trackable way. Clear, consistent communication keeps everyone aligned and reduces rework.

Equipment Downtime

Old or poorly maintained equipment leads to production delays, inconsistent quality, and higher repair costs. Technicians may spend time troubleshooting machines or waiting for repairs, while deadlines slip and output slows.

Solution: Build a preventive maintenance schedule for all equipment and assign responsibility for upkeep. Log all equipment issues and track recurring problems. When repair costs or downtime accumulate, it may be time to consider an upgrade. Plan equipment purchases around seasonal promotions, tax planning, or trade show discounts to maximize value.

Lack of Cross-Training

Labs that rely too heavily on a few key individuals can find themselves in trouble when someone is out sick or on vacation. Work piles up, deadlines are missed, and quality may suffer.

Solution: Cross-train staff in key areas of production. Start with the most time-sensitive or backup-prone steps and create written SOPs (standard operating procedures). Encourage a culture of knowledge sharing so your team can flex to meet demand as needed.

Waiting on Doctor Feedback

Cases often stall when labs are waiting on feedback, approval, or additional information from the prescribing dentist. This dead time adds up quickly, especially if the case is already in progress.

Solution: Use automated messaging or case tracking software to remind clients when feedback is needed. Consider building in deadlines for responses and following up systematically. For trusted accounts, you may be able to implement standing preferences to minimize back-and-forth on routine cases.

What to Take Away

Efficiency doesn’t always require a massive investment—it starts with a willingness to identify and correct what’s already slowing you down. From intake and communication to equipment and scheduling, the top time wasters in dental labs are often the most fixable. Streamlining your workflow boosts productivity, increases job satisfaction, and improves service to your clients. Start small, involve your team, and focus on systems that support long-term success.